ELECTRICAL INSTALLATION CONDITION REPORT

All electrical installations should be subject to regular checks the frequency of which will depend on the type of installation eg: installations within residential properties should be a maximum of ten years between checks, whereas a construction site may require a check at three monthly intervals.

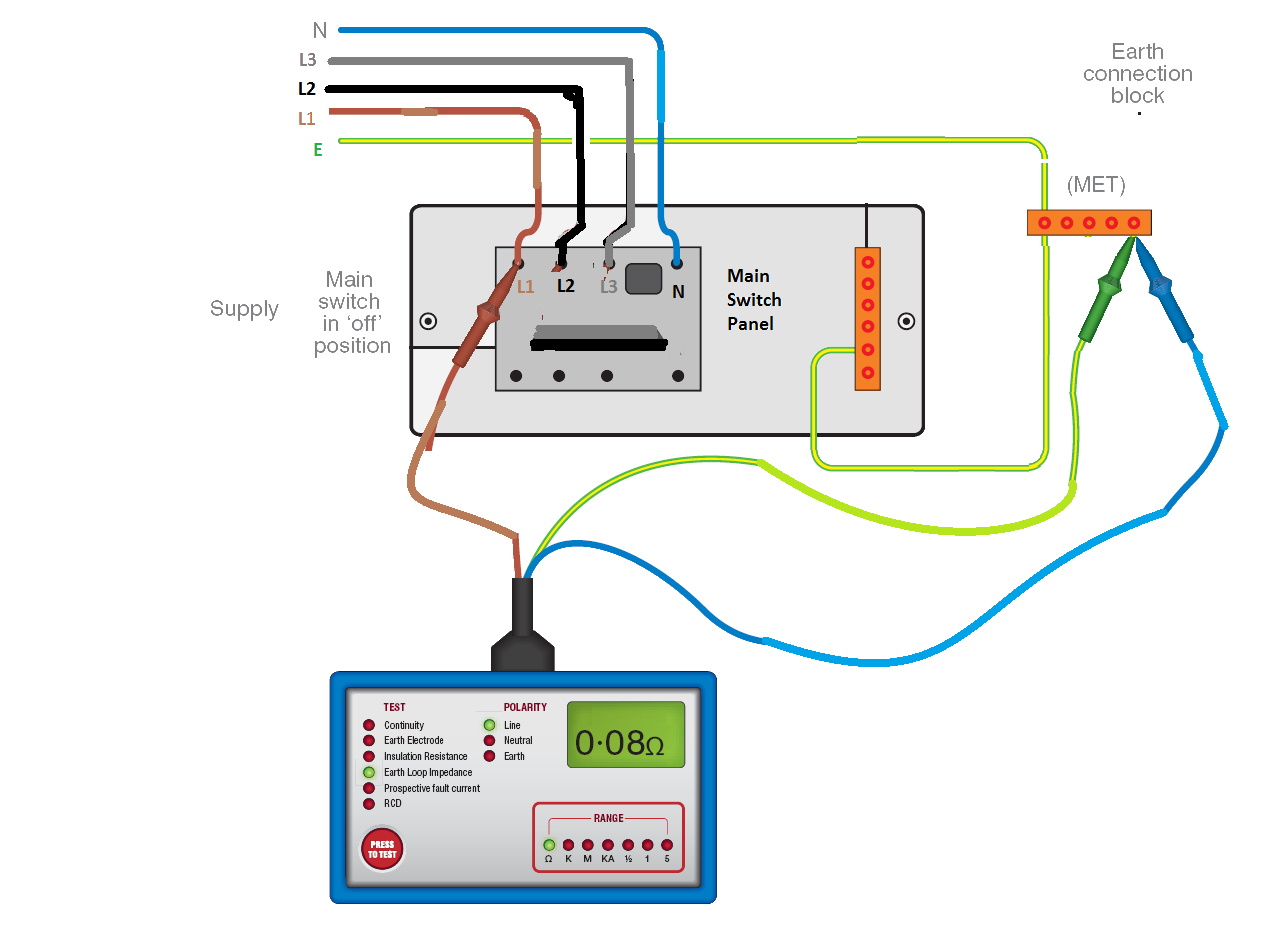

The Electrical Installation Condition Report includes a thorough visual inspection looking at all aspects of the installation together with extensive testing.

Any non-compliance issues are identified and categorised and an overall assessment is provided as to whether the installation is safe to continue using in its current state.